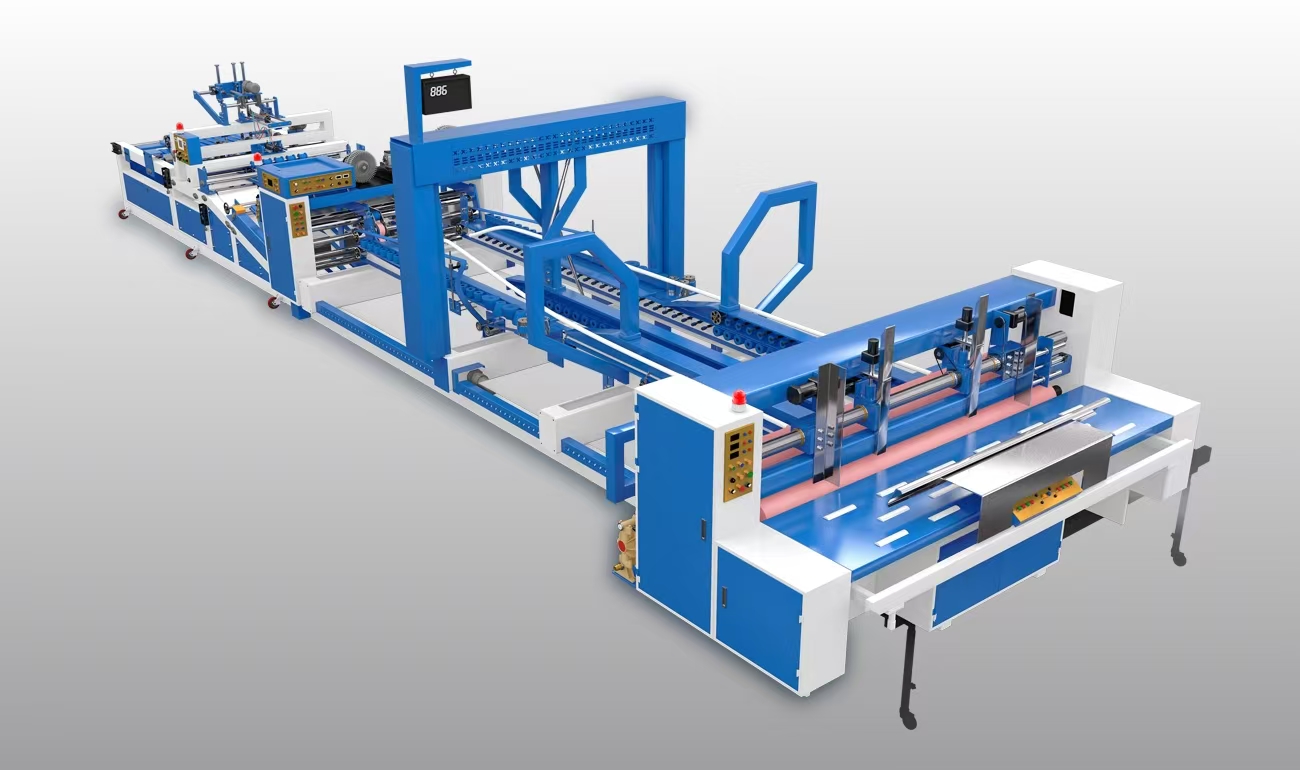

When it comes to high-efficiency box forming and closing, Giant offers the ideal solution with its Automatic Folder Gluer / Stitcher Counter Ejector. This machine is specifically designed for the final stage of corrugated box production, handling folding, gluing or stitching, and automatic stacking with precision and speed.

Whether you're producing standard cartons or heavy-duty packaging boxes, this system helps you achieve seamless automation, reduce manual labor, and maintain consistent output quality.

A Complete End-of-Line Packaging Solution

Our automatic folder gluer stitcher system is suitable for handling a wide range of corrugated board thicknesses and box styles. The counter ejector automatically counts and stacks finished boxes, keeping your production line smooth and organized.

Folding Unit

Ensures accurate folding of carton blanks into precise shapes with intelligent alignment and correction systems.

Gluer or Stitcher

Available in gluing mode, stitching mode, or combined mode, based on your production needs:

- Glue: For clean, seamless closures ideal for lighter packaging

- Stitch: For durable, heavy-load boxes requiring reinforcement

- Glue & Stitch Combo: For added strength and appearance

Counter Ejector

Automatically stacks and counts boxes for easy bundling, reduces manual handling, and increases efficiency.

Key Features of Giant's Machine

- High-speed folding and closing operation

- Servo-controlled systems for accuracy

- One-operator-friendly design with smart interface

- Suitable for both single-wall and double-wall corrugated boards

- Memory settings for repeat orders and fast job changeovers

Why Choose Giant's Folder Gluer Stitcher Line?

At Giant, we understand the importance of automation in end-line processing. Our equipment is built with industrial-grade components and smart controls, ensuring durability and long-term performance even in high-output production environments.

You can expect:

- Stable and accurate performance under continuous operation

- Customization to meet box types and production scales

- Excellent after-sales technical support and maintenance

Join hundreds of global packaging manufacturers who trust Giant to optimize their production lines.